Cost Control, ESG Implementation, Efficiency Improvement

Why is it needed?

The Importance of Electricity Management?

Cost Control

Environmental Protection

Efficient Operation

Supply Stability

Regulatory Compliance

Technological Innovation

Electricity is a significant operational cost item. By saving Electricity, businesses can reduce their Electricity bills, lower costs, and enhance competitiveness. Electricity consumption has a major impact on the environment, especially in terms of CO₂ emissions. Effective Electricity management helps reduce energy waste and lower the carbon footprint.

Managing Electricity efficiently ensures that facilities and equipment operate optimally. Optimizing Electricity usage in facilities can extend equipment lifespan, reduce failures, and lower maintenance needs.

Proper Electricity management helps ensure supply stability, preventing power outages and production interruptions. This is particularly crucial for critical facilities. Additionally, many countries and regions have Electricity efficiency and environmental regulations. Good Electricity management ensures compliance, helping businesses avoid fines and legal issues.

Modern management systems leverage advanced technologies, including instrumentation, data analytics, automation, and artificial intelligence, helping businesses remain competitive and enabling more efficient operations.

Feature Description

Improve Work Efficiency by Over 40%!

EMS Intelligent Electricity Management System provides real-time data and instant alerts, eliminating the labor cost and time required for manual inspections. By analyzing data, users can perform predictive maintenance in real-time, taking preventive measures before issues escalate, thereby reducing the risk of sudden failures.

Additionally, it helps predict equipment failures and maintenance needs, identifying potential causes of anomalies, allowing engineers to conduct targeted maintenance, minimizing downtime, and improving equipment efficiency.

• Automated meter reading eliminates manual inspections and reduces time costs.

• Alerts for abnormal conditions enable instant predictive maintenance.

• Provides detailed data to shorten repair time.

• Automatically generates reports and statistics, reducing manual calculations.

The system automatically collects data and generates statistical reports, including energy usage trends, electricity cost comparisons, and equipment performance evaluations. This reduces the need for manual data analysis, enhances data usability, and provides more accurate optimization recommendations.

Feature Description

Helps Save Over 30% of Energy!

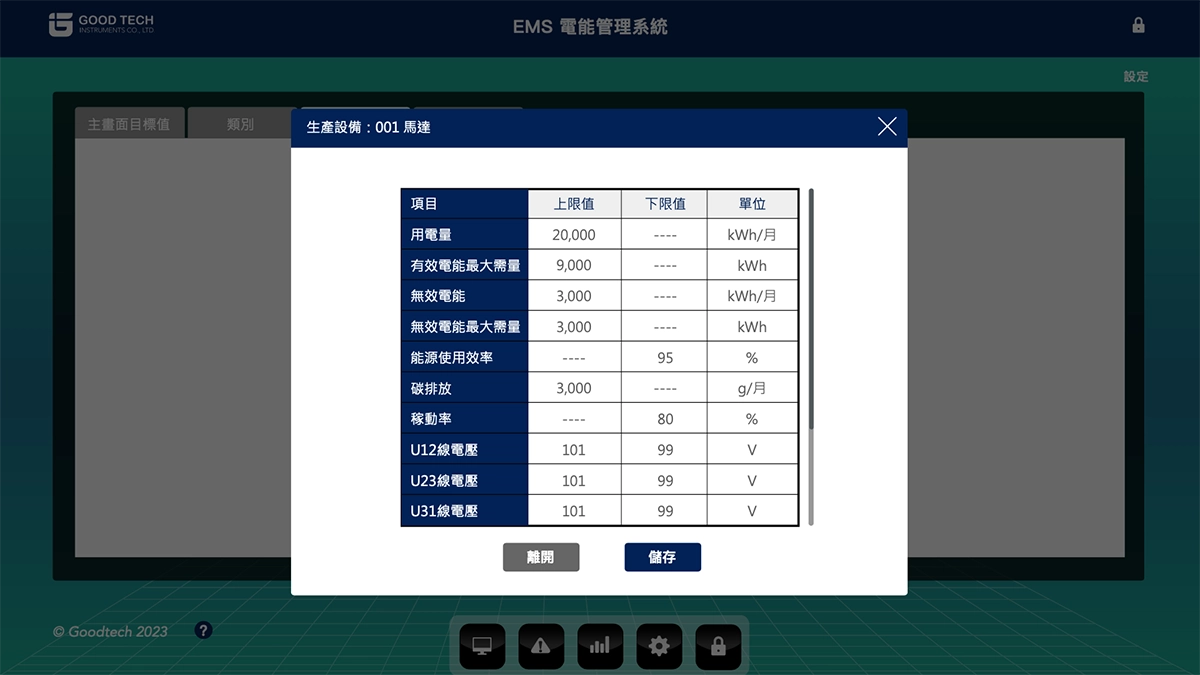

EMS Intelligent Electricity Management System generates detailed data reports, helping users understand energy consumption patterns and identify energy-saving potential. The system allows users to set energy-saving target values and customize parameter thresholds, enabling data-driven decision-making. By collecting various parameters, cross-referencing data, and leveraging AI training, the system can predict potential equipment failures in advance.

• Set energy-saving targets to identify potential savings.

• Customize parameter thresholds and receive alert notifications.

• AI predicts equipment failure points to prevent unexpected shutdowns.

• Energy-saving recommendations optimize equipment operating time.

The system provides energy-saving recommendations by optimizing equipment operating times to ensure electricity is used during the lowest-cost periods. It helps users comprehensively evaluate various factors and develop strategies to gradually reduce energy costs and improve equipment efficiency.

Feature Description

Equipment Utilization & Carbon Calculation for Sustainable Development

EMS Intelligent Electricity Management System manages equipment utilization to prevent unnecessary carbon emissions caused by idle, halted, or inefficiently running equipment. This helps reduce energy waste and lower carbon emissions.

By tracking and calculating carbon emissions, businesses can identify major sources of emissions and develop strategies to reduce them. This assists in minimizing the company’s carbon footprint, ensuring compliance with government regulations and environmental goals, while also avoiding legal risks and fines.

Furthermore, carbon emissions management enhances corporate social responsibility, supports long-term sustainability goals, improves supply chain transparency, and promotes green and eco-friendly practices, ultimately achieving the objective of corporate sustainable development.

Feature Description

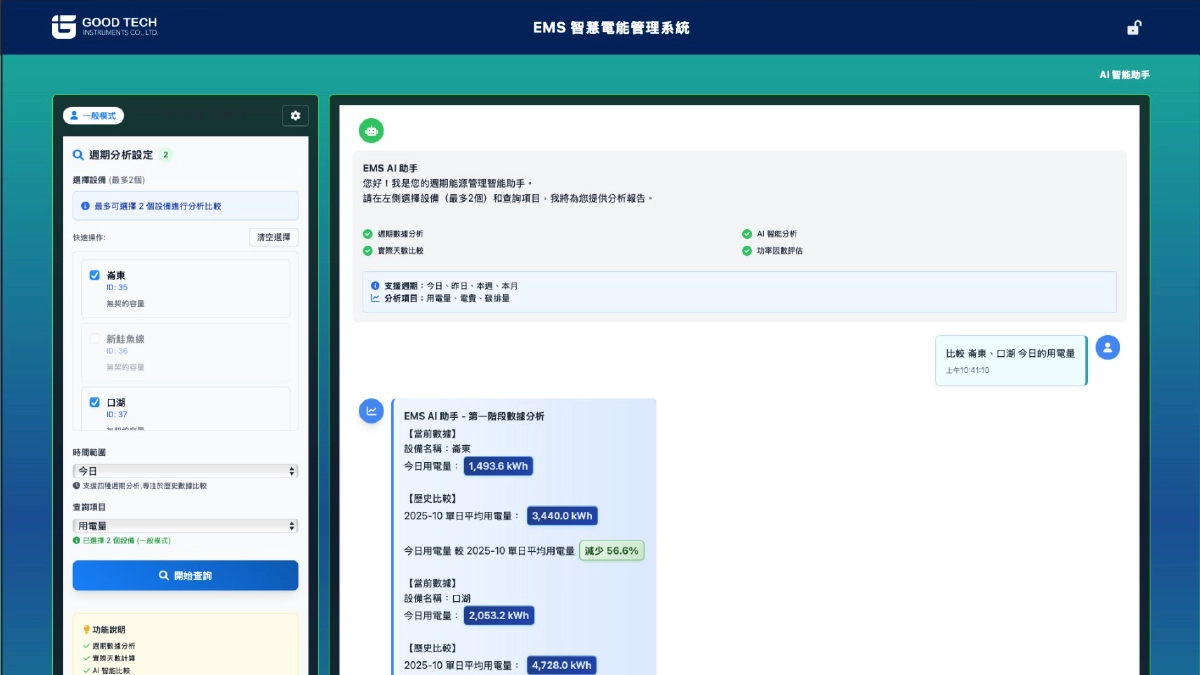

Transforming Energy Management from Bookkeeping to Decision-Making

There is plenty of data, but no one has the time to truly understand it?

The EMS Intelligent Energy Management System records every real-time power usage.

Load curves for each floor and each production line are fully preserved.

The changes between peak and off-peak hours are drawn into lines that look elegant

but are often difficult to interpret. Over time, the system accumulates what becomes

a massive “mountain of power data.”

Integrating AI into EMS is not just adding a “chat window.” Instead, it attempts to

organize the knowledge that was once scattered across reports, presentations, and

engineers’ minds into live knowledge—information that can be summoned and

queried at any time.

For managers without an energy background, this interactive approach greatly lowers the barrier to entry, making “reading power data” no longer a task solely for the energy department.

Feature Description

Integrated Command Center – Monitor Anytime, Anywhere

EMS Intelligent Electricity Management System allows various data to be uploaded to the cloud or integrated into an IIoT Dashboard, enabling users to manage their facilities more efficiently.

The system includes a responsive web viewing feature, accessible via the local intranet. Users can monitor data using smartphones, tablets, or laptops without login restrictions. By simply connecting to a fixed IP intranet and opening a browser, users can instantly check equipment status and energy consumption across their facilities—anytime, anywhere.

Benefits

Efficiency Improvement & Driving Net-Zero Carbon Emissions

Improve Equipment Efficiency

Monitor equipment status changes to enhance utilization rate. Understanding equipment conditions helps schedule maintenance and reduce production line downtime.

Fault Cause Analysis

Identify frequent causes of equipment anomalies and predict potential issues. Data-driven analysis prevents subjective human judgment.

Reduce Costs & Expenses

Lower labor and energy costs, shorten downtime for maintenance, and maximize energy savings through optimized calculations.

Drive Net-Zero Carbon Emissions

Support carbon emission management and reduce the carbon footprint. Through energy management, lower consumption, implement ESG initiatives, and achieve sustainable operations.

Electricity-Saving Goals

Optimization Measures

Setting reasonable energy-saving goals is key to conserving electricity. Establishing specific and achievable targets while actively implementing energy-saving measures can maximize potential savings. With the EMS Intelligent Electricity Management System, users can leverage energy-saving recommendations and optimization measures to manage energy usage more effectively and reduce energy waste.

UI Features

Consolidate Data to Identify Energy-Saving Potential!

• 30-minute real-time monitoring

• Power consumption breakdown by device type

• Recommended optimal power usage periods

• Energy-saving data statistics and target values

• Power consumption trends for various parameters

• Equipment electricity cost comparison

• Abnormal event alert records

• Peak demand anomaly detection

• AI Smart Assistant

UI Features

Various Trend Analysis Queries

Off-Peak, Peak, and Mid-Peak Trend Analysis

Understand the usage distribution of off-peak, peak, and mid-peak periods, helping users schedule power usage at optimal times to reduce electricity costs.

Operation, Standby, and Downtime Utilization Analysis

Track machine utilization rates to avoid unnecessary energy waste due to idle or prolonged downtime. Helps optimize production efficiency and improve OEE.

Carbon Emission Analysis for ESG Compliance

Analyze carbon emissions by equipment type to assist in carbon inventory tracking, carbon footprint assessments, and ESG planning for sustainable facility management.

Monitor Machine Status with Detailed Data Logs

Real-time logging of power consumption data for each machine. Users can analyze trend charts to identify anomalies and their root causes.

UI Feature Screens

Flexible Addition of Device Points

Simple structure for easy expansion, giving you greater management flexibility

The system features a simple architecture and fast installation, allowing flexible expansion based on on-site operational needs—without requiring large-scale construction.

The device list displays real-time information, enabling precise management of every device status. With customizable categories and flexible point additions, you can create new monitoring points for your facility at any time with just a few simple steps, ensuring you are always ready with the best planning for your plant.

UI Feature Screens

Abnormal Event Log Reports

Instant alerts for abnormal power usage with quick root cause identification

Do you know which machines are consuming excessive power, and which ones are running with power that is too low?

The system provides real-time abnormal alert functionality, sending warning messages immediately via email.

At the same time, it records the time, location, and data of each abnormal event, helping users quickly analyze the root cause, avoid equipment damage or production interruptions, and reduce the impact of unexpected incidents on operations. In addition, users can add their own notes on the cause for each abnormal record, making data tracing and review much easier.

UI Feature Screens

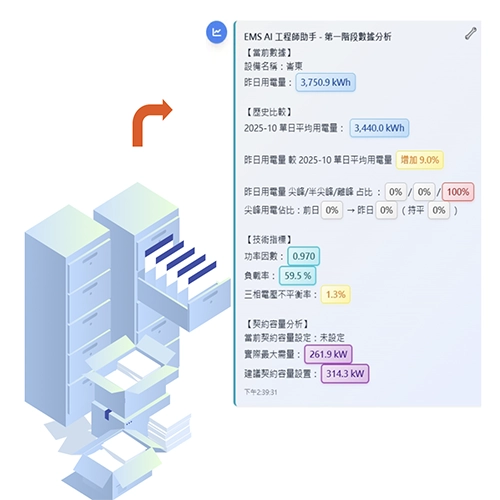

AI Smart Assistant

Speeding up data lookup while surfacing key insights and recommendations

When an abnormal power usage event occurs, the AI Assistant compares past data from the same time period

and corresponding equipment—such as power consumption or power factor—to see whether similar issues have

occurred under comparable conditions. It then summarizes these findings into a concise sentence as

“actionable improvement suggestions.”

This AI Assistant does not replace the original screens and charts. You can still manually click into each page to review details. It simply gives you a more intuitive shortcut by letting the system point you in the right direction first.

Application Targets

Suitable for Any Energy-Consuming Facility

Examples: Semiconductor industry, petrochemical plants, wastewater treatment plants, power companies, infrastructure, railway transportation, residential property management, inspection and meter reading, pharmaceutical and food industries, as well as agricultural and aquaculture sectors.

Architecture Overview

Ensuring Safe Production & Enhancing Equipment Efficiency

Support

Other ESG-Related Topics