Abnormalities Caused by Insufficient Air Pressure in the Glue Dispensing Machine?

Case|Abnormalities Caused by Insufficient Air Pressure in the Glue Dispensing Machine?In automated dispensing systems (also known as glue dispensing), the air pump plays a central driving role. The stable air pressure provided by the air pump is essential for transferring the adhesive from the storage tank to the dispensing valve. When the air pump operates normally, the adhesive can be dispensed onto the product surface with a stable and precise flow rate. However, if any malfunction occurs, it directly impacts process quality, yield, and equipment stability.

Operating Principle of the Air Pump

The basic operation of an air pump relies on compressed air to drive an internal piston, continuously pushing adhesive toward the dispensing valve according to control logic. The compressed air is regulated by solenoid valves to control intake and exhaust, coordinating with the piston’s reciprocating motion to create suction and discharge actions. This mechanism drives the adhesive forward under constant pressure, completing the process of

“pushing adhesive → opening control valve → dispensing”.

Although this structure is simple, it heavily depends on pressure stability and the mechanical integrity of the pump piston. Any imbalance in pressure, piston jamming, or air leakage may result in flow interruptions or deviation in output volume, ultimately affecting the quality of dispensing.

Impact of Insufficient Air Pressure in the Glue Dispensing Machine

When an abnormality occurs in the air pump, its impact on dispensing quality can be categorized into the following major aspects:

1. Uneven Dispensing Volume: Unstable air pressure leads to inconsistent glue output, potentially causing glue accumulation or insufficient application, resulting in weak bonding or overflow.

2. Glue Breaks: If the piston movement is inconsistent or experiences internal friction, intermittent "air shots" may occur during continuous dispensing, resulting in broken glue lines.

3. Dispensing Delay: Delay in pressure buildup causes slow start-up of dispensing, leading to glue drops being displaced.

4. Dripping Due to Failed Suction Back: Abnormalities affect the post-dispensing suction-back function, causing the nozzle to drip and contaminate the product or machine.

5. Abnormal Noise and Overheating: Insufficient lubrication or component wear can cause pump malfunction, generating unusual noise or even heat melting, further accelerating system failure.

Monitoring Description

DB Glue Dispensing Monitoring System

By monitoring the air supply to the air pump, the system captures analog signals via a pressure gauge. Through edge computing, it analyzes waveform features including average value, maximum value, and standard deviation. Upper and lower thresholds are set, and feature values are uploaded to the FDC (Fault Detection and Classification) system for effective management of air pump operation across all machines.

Measurement Conditions

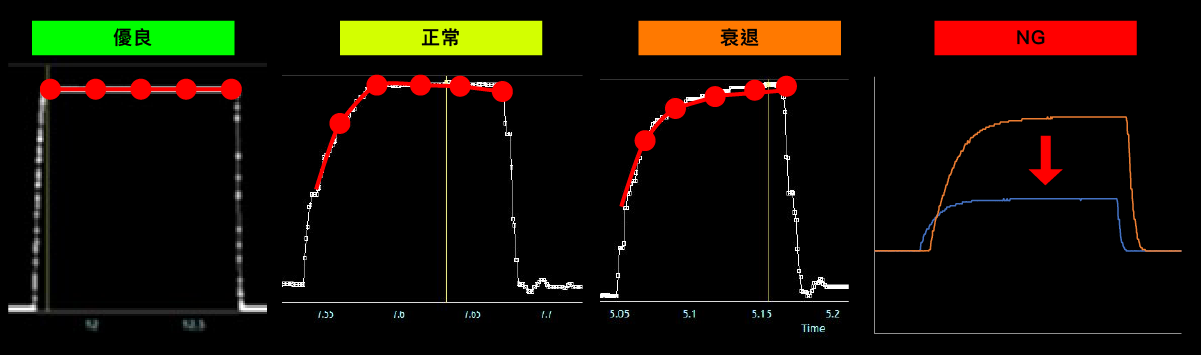

AIR PUMP OFFLINE Measurement (Location 1)

First-generation AIR PUMP, manually triggered dispensing at approximately 100ms, maximum vacuum suction, dispensing pressure 100 KPa.

Second-generation AIR PUMP, dispensing set time at 100ms, maximum vacuum suction, dispensing pressure 100 KPa.

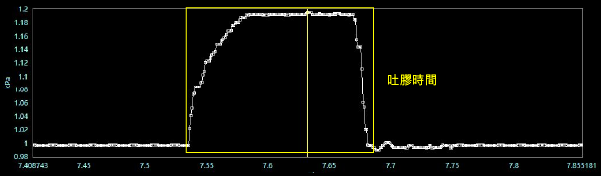

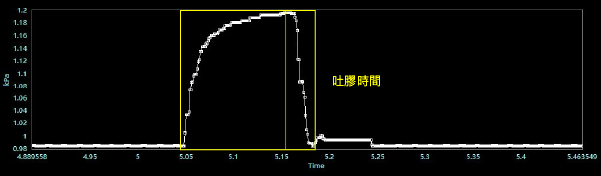

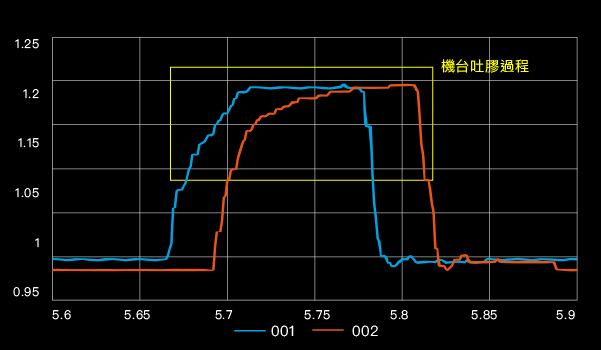

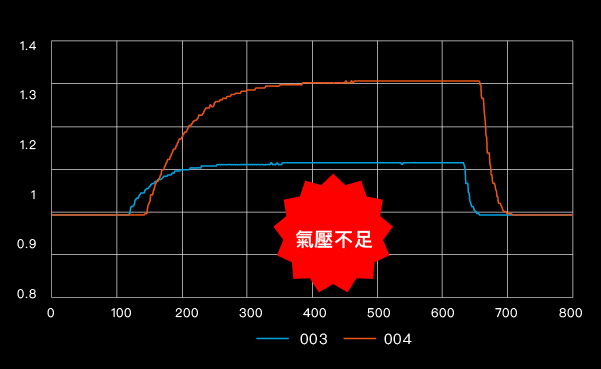

Comparison of AIR PUMP Actuation Air Pressure Signals

・Comparison of dispensing duration across different machines.

・Optimal dispensing condition is achieved when pressure remains stable from start to end.

AIR PUMP ONLINE Measurement (Location 2)

Insufficient air pressure, pressure drop, and discontinuous dispensing airflow.

Normal dispensing

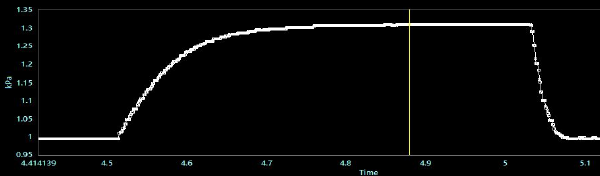

Differences Caused by Insufficient AIR PUMP Pressure

Simulation of dispensing failure due to insufficient air pressure

・Production line machine: dispensing time 500ms / dispensing pressure 86 KPa.

・Abnormality caused by air insufficiency due to split air pipe on the production line.

・During testing, air supply was clearly insufficient after splitting the outlet pipe, causing dispensing failure.

・Dispensing returned to normal after increasing pressure to 149 KPa.

Measurement Results

・Monitor dynamic air pressure signals for each dispensing action

・Ensure consistent air volume for every operation

・Set monitoring thresholds according to product-specific dispensing air volume and precision standards

・Store data logs for each action to support future anomaly analysis

・Generate trend charts from interval data of dynamic processes to serve as a secondary standard for anomaly detection

Conclusion

In summary, aging of the air pump leads to air leakage and intermittent pressure fluctuations. The result is skewed glue lines on product surfaces and adhesive residue on components, increasing defect rates, requiring manual cleaning and rework—severely impacting production cycle times and labor costs. This type of abnormality is difficult to detect in its early stages and is often only noticed through declining yield, resulting in missed opportunities for timely maintenance. By introducing the DB Glue Dispensing Monitoring System, the root cause can be precisely identified.

Although the air pump is only one component of the overall dispensing system, it is highly correlated with dispensing stability and process yield. Once it malfunctions, it creates a ripple effect impacting product quality, line rhythm, and manpower costs. Therefore, manufacturers are advised to establish a monitoring and maintenance system for air pumps at the source, using data-driven methods to enhance response speed and diagnostic accuracy. Only through such measures can high-yield, high-efficiency automated production truly be achieved.