Track Production Line Status in Real-Time, Seamless Digital Upgrade.

Why Is It Needed?

Why Does the Three-Color Light System (Andon System) Need Management?

Are You Still Ignoring Idle Time in Your Production Line?

Are you letting low equipment utilization rates persist? How can you effectively monitor factory utilization?

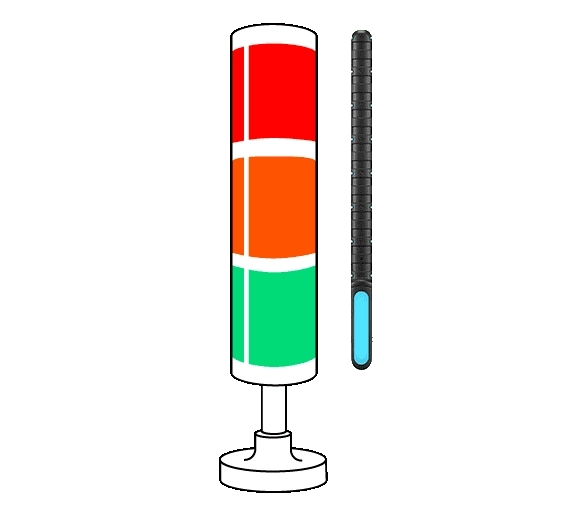

In fact, the three-color light system in the factory represents the real-time status of equipment at every moment. By collecting this status data, we can calculate the factory utilization rate, gain insights into the operational status of process equipment, and ultimately improve production efficiency.

GoodTech’s Equipment Utilization Management System is compatible with various types of equipment and comes with low implementation costs. By installing sensors on the three-color lights, the system can be quickly set up to integrate and provide real-time statistical management of production line equipment across the factory.

Pain Points

Common Factory Management Challenges?

Are you struggling to accurately monitor production line equipment?

How long has the equipment been idle?

Is there an immediate response when issues arise?

How many machines are constantly under repair?

How much time is spent waiting for materials?

With labor shortages, how can one person manage multiple machines?

Developing and implementing management systems can be costly and may not be compatible with older equipment.

How can production scheduling be planned efficiently?

With diverse equipment types, how can factory utilization rates be clearly visualized?

How can digital management be implemented seamlessly without disruption?

Solution:A low-cost management system with no lengthy development periods, enabling instant digitalization to address factory pain points effectively.

Unable to Monitor

Production Line Status

Issues Cannot Be

Addressed Immediately

One Person Managing

Multiple Machines

High Cost of

Management Systems

Outdated Equipment

Unable to Upgrade

Diverse Equipment,

Difficult to Manage

Feature Overview

Easy to Use with No Technical Barriers

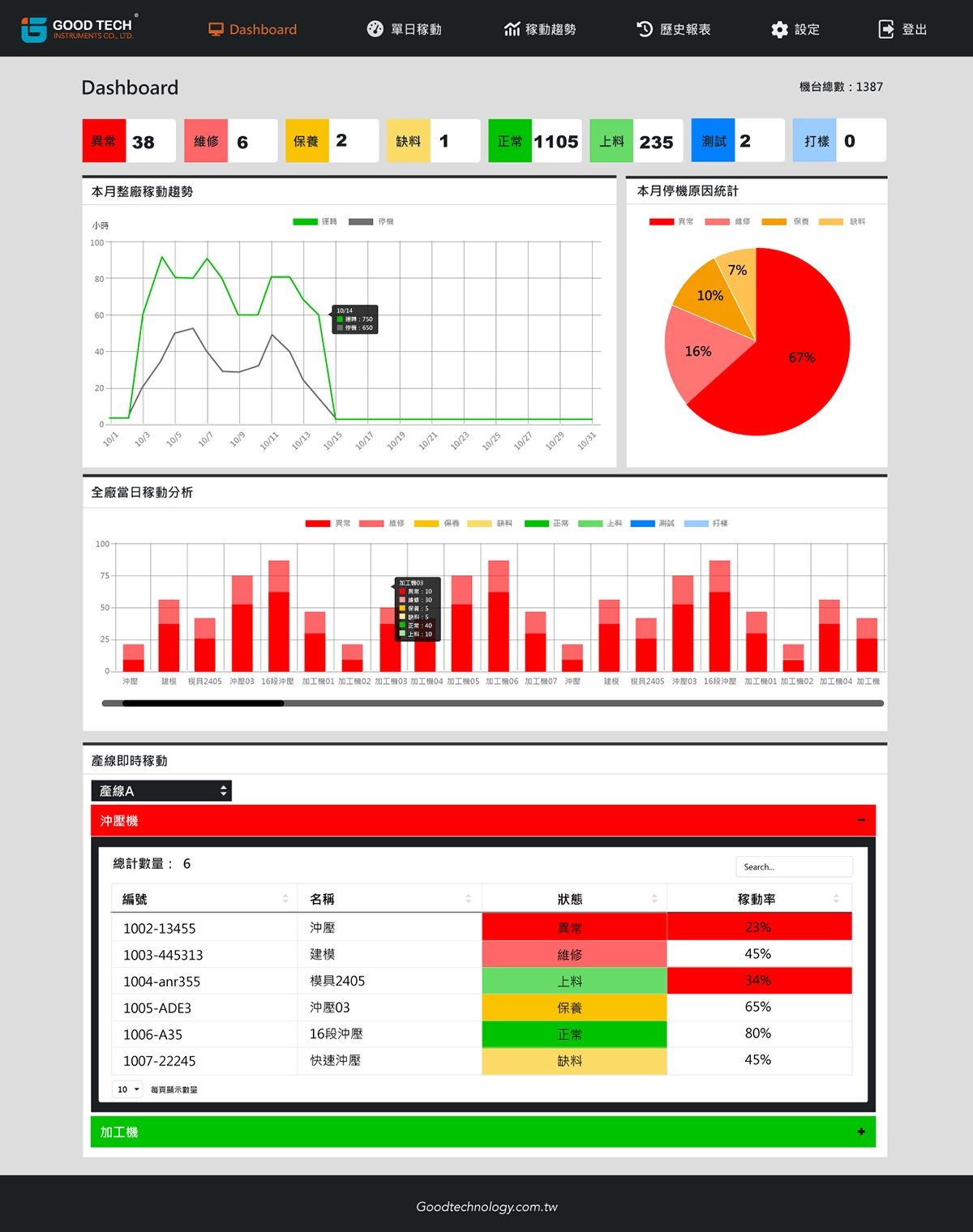

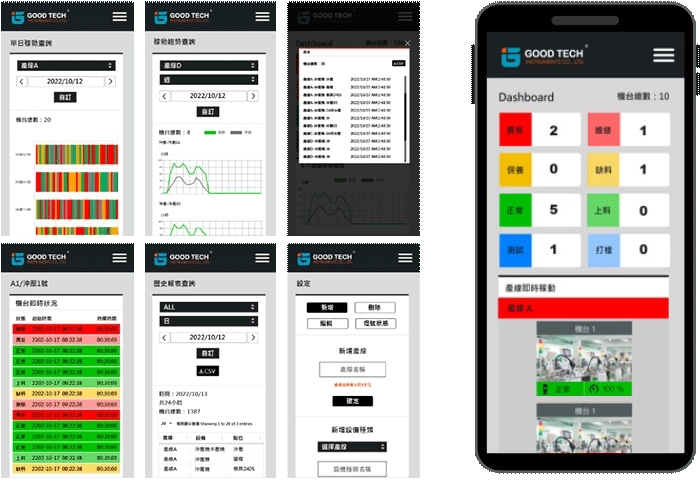

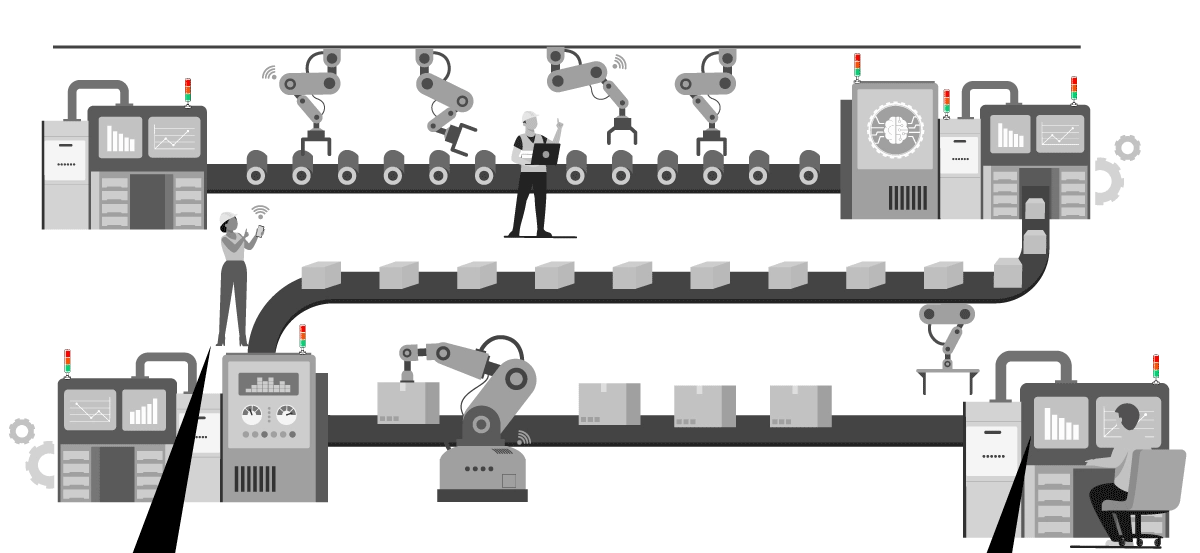

OEE Equipment Utilization Management SystemThe main DASHBOARD provides a clear overview of the entire factory’s equipment utilization at a glance. The system data can be integrated with third-party systems such as ERP, MES, and CRM, accelerating the digital transformation of smart factories. By automating processes, it reduces labor costs and makes data management more efficient.

This system is suitable for various factory equipment equipped with three-color indicator lights, such as CNC machines, cutting machines, and more. The accompanying optical sensor offers quick and easy installation, collecting data in real time. The system consolidates various data sources, visualizes equipment status, and calculates utilization rates. With graphical data management, users can easily understand production line performance and optimize operations.

Feature Overview

Compatible with Tablets and Smartphones

OEE Equipment Utilization Management System Designed with responsive web design (RWD), the system adapts seamlessly to various screen sizes for optimal viewing. It supports iOS, Android, and Windows operating systems, ensuring compatibility across devices.

Simply connect via an IP address or local network, with unlimited user logins, allowing remote access from home. Users can conveniently monitor production line utilization and equipment status in real time using various smartphones and tablets, making factory management easier and more efficient.

Feature Overview

Flexible Transmission Options

Are you worried about being restricted by system architecture when using a management system?

The OEE Equipment Utilization Management System offers users the flexibility to choose their preferred data transmission method. Whether storing data on a local server or managing it via the cloud, the system ensures robust security measures.

This flexibility helps avoid limitations related to data transmission, storage methods, or hardware brand restrictions, providing a more adaptable and secure solution for your factory management needs.

Feature Overview

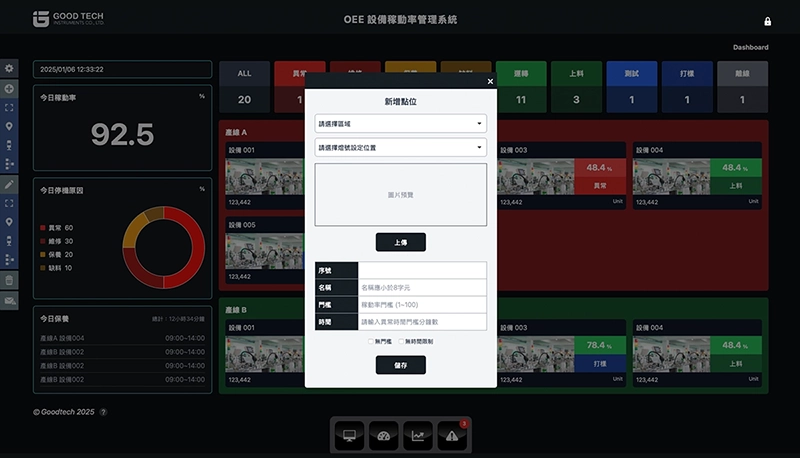

Gradual Expansion with Additional Monitoring Points

Is your factory still in the process of transitioning and upgrading? Are you dealing with a mix of new and old equipment, with phased budgets delaying the implementation of a three-color light management system on some machines?

No problem! With the OEE Equipment Utilization Management System, expansion doesn’t have to happen all at once. Thanks to its flexible architecture, there are no limitations on the number of monitoring points. The easy-to-install sensors allow factory personnel to quickly and independently add new monitoring points in the future, ensuring a seamless and scalable upgrade process.

Easy Implementation,

Data Visualization

The OEE Equipment Utilization Management System provides real-time consolidation and display of equipment status while calculating utilization rates. With graphical data management, users can easily gain clear insights at a glance.

UI Feature Screen

Understand Equipment Operation Efficiency

Operation Trend Query: Understand Equipment Efficiency

Some machines seem to be running every day, but frequent stoppages could mean their efficiency is declining.

The OEE Equipment Utilization Management System provides trend analysis for each machine’s operation rate,

helping you understand long-term operational efficiency for every piece of equipment.

UI Feature Screen

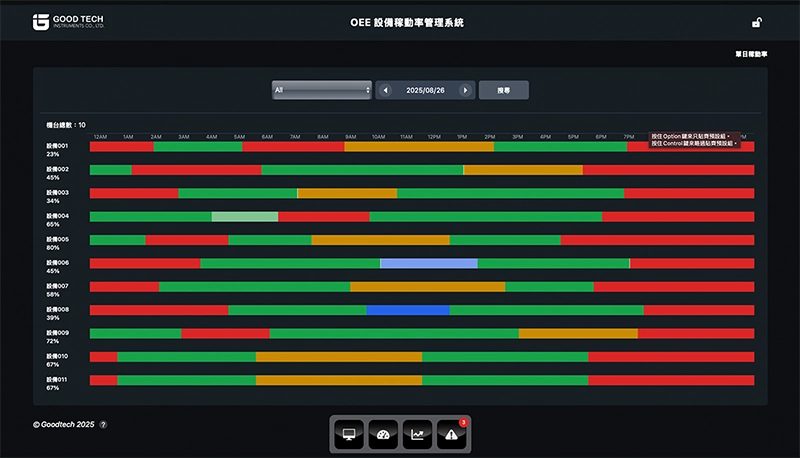

Quickly Identify Abnormal Utilization

Daily Operation Query: Quickly Identify Anomalous Equipment

Is your production line sitting idle too long? Equipment problems not addressed in time?

These issues lead to hidden costs. With the OEE Equipment Utilization Management System daily operation query function,

you can quickly pinpoint equipment with abnormal utilization and improve production line efficiency.

UI Feature Screen

Help Optimize Production Line Utilization

Abnormal Record: Custom Thresholds and Alerts

The Equipment Utilization Management System allows users to set utilization thresholds when configuring data points.

Once the utilization rate drops below the threshold, the main screen displays a red alert light to remind users to investigate,

helping factories improve utilization rates and production output.

In addition, users can add notes about causes or resolutions, making production line handovers smoother and preventing the same issues from recurring.

UI Feature Screen

Provide Analytical Management Data

Historical Report Query: Provide Data for Analysis

The OEE Equipment Utilization Management System offers historical data report export functionality.

Users can select specific time ranges for report queries, avoiding unnecessary data searches

and time-consuming pre-processing. This makes it easier to trace historical information

and simplifies data analysis.

UI Feature Screen

Gradually Expand Measurement Points

Point Configuration: Flexibly Add Measurement Points

Is your factory still in the process of system implementation and transformation? Budget limitations preventing a full monitoring system deployment?

With the flexible architecture of the Equipment Utilization Management System, you can expand and add measurement points step by step according to your needs. There is no limit on the number of installation points, making it ideal for factories in the process of scaling up.

UI Feature Screen

Real-Time Monitoring on Mobile

Monitoring Process

Monitoring in Just Three Steps

1. Attach Sensors to the Aden Light

2. Add Monitoring Points and Await Data

3. Monitor Equipment Operations and Production Line Utilization

Architecture Description

Monitor Production Line Status and Improve Utilization

Equipment with three-color signal lights, such as machining centers, cutting machines, etc.

Monitoring Benefits

Low Implementation Cost, Easier Management

1. Low Technical Barriers, Easy Operation

No complex setup is required, allowing users to manage equipment effortlessly without technical expertise. The system is designed for ease of use, with no need for programming skills—general users can install it themselves and quickly become proficient with the software.

2. Low Implementation Cost, Quick Deployment

By utilizing existing three-color indicator lights on factory equipment, the system can be implemented without the need for extensive hardware, wiring, or long development lead times. Even older machines can be seamlessly upgraded without disruption.

3. External Sensor Integration, Compatible with Any Equipment

Factories have a wide variety of equipment, making data extraction challenging. With external sensors, any equipment featuring indicator lights—whether three-color, four-color, or two-color—can be effectively monitored and managed.

Too many indicator lights in the factory? Hard to keep track? The system organizes everything for you!

By using external sensors to transmit indicator light data to the system, operators no longer need to physically monitor each machine. Instead, all equipment statuses can be unified in the system, enabling a single person to manage multiple machines efficiently. This saves manpower and time costs.

When an issue arises, the system provides immediate alerts and facilitates quick reporting, reducing response times. Additionally, the system consolidates production line utilization data, providing management with accurate, real-time insights to make informed decisions and improve Overall Equipment Effectiveness (OEE).

By adopting this solution, factories can accelerate their transition to smart manufacturing and digital management, improving operational efficiency and competitiveness.

Improve Production Line Efficiency

Enhance Equipment OEE

Reduce Labor and Time Costs

Reduce Response Time to Issues

Make Timely and Accurate Decisions

Upgrade Your Factory to a Smart Factory

Applications

Suitable for Various Equipment with Indicator Lights

For example: Semiconductor industry, automotive manufacturing, petrochemical plants, power companies, food factories, pharmaceutical manufacturing, laboratories, traditional processing plants, stamping plants, textile mills, paper mills, printing factories, etc.

Applications

Objects of use

1. Equipment operators

When one person manages multiple equipments, it is necessary to avoid failure to timely discover when equipment abnormalities or machines are idle.

It is convenient to uniformly calculate the utilization rate and display abnormal equipment in real time.

2. Factory managers

Can master the time management of factory equipment, such as: operation time, downtime, maintenance time, operation test, etc.

Can trace the working time of the factory and shorten the idleness of the production line.

Performance Cases

Other utilization rate related