The Motor is Making Obvious Noise – Which Component is Faulty?

Diagnostic Performance|The Motor is Making Obvious Noise – Which Component is Faulty?A machining center has a complex structure, and even minor component failures can affect the product. When the motor produces significant noise, how can we quickly identify the faulty part?

Characteristics of Machining Processes

Machining equipment uses motor power and belt-driven structures to rotate the workpiece and cutting tools, enabling cutting operations. Through digital computer-aided production, the process becomes more precise and efficient.

Component Fault Measurement

When the motor or pump of precision machinery produces excessive noise, it clearly indicates an abnormal condition. How can we rely on experience to determine which component is problematic and locate the root cause?

Solution and Monitoring Description

VMS-PM Dynamic Analyzer / SMS-RC Rotating Equipment Diagnostic Analyzer

By measuring rotor vibration quality, you can identify issues without the hassle of disassembling and reassembling the machine. Component-based sectional measurements help pinpoint abnormal areas for repair. This test includes: 90-degree measurement point, 90-degree upper section, transmission shaft, and tool end.

Measurement Status

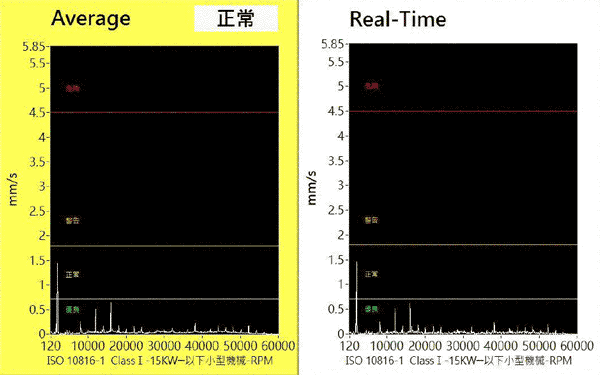

Measurement Item 1

90° Measurement Point

Rotor Quality Assessment: Normal

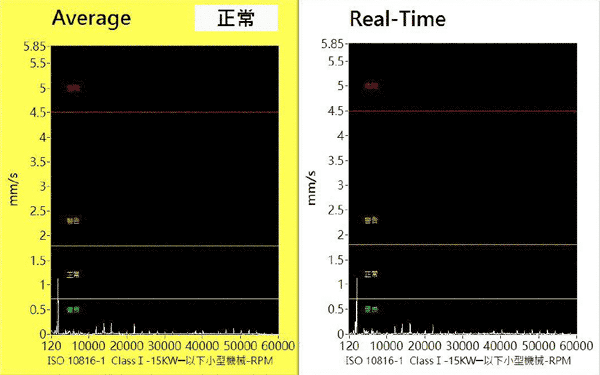

Measurement Item 2

90 度上部量测点

转子品质判定:正常

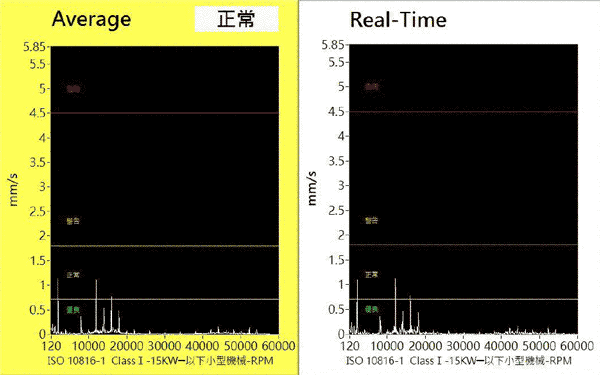

Measurement Item 3

Transmission Shaft Measurement Point

Rotor Quality Assessment: Normal

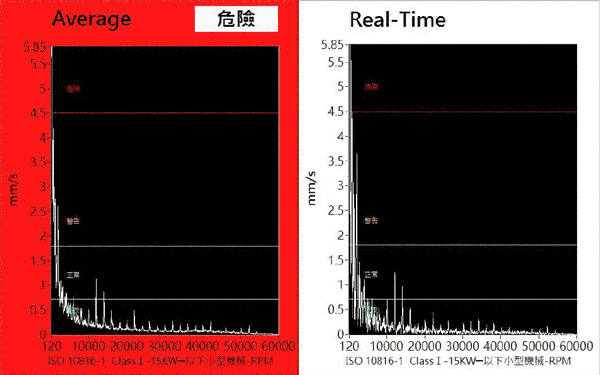

Measurement Item 4

Tool End Measurement Point

Rotor Quality Assessment: Abnormal

Measurement Conclusion

An abnormality was detected at the tool end. It is recommended to stop the machine immediately for troubleshooting. By using the VMS-PM Mechanical Dynamic Analyzer, errors can be diagnosed more efficiently, identifying abnormal parts and causes. With regular inspection measurements, maintenance can be carried out once warning signals are detected, preventing unexpected downtime.

VMS-PM Mechanical Dynamic Analyzer